Introduction

Weed management in organic fruit and vegetable production systems is considered a major challenge (Kropff and Walter Reference Kropff and Walter2000; Pupalienė et al. Reference Pupalienė, Sinkevičienė, Jodaugienė, Bajorienė and Pilipavičius2015). Without synthetic herbicides, organic growers rely mainly on preemergence and postemergence mechanical control, cover crops, intercropping, or mulches to manage weeds (Bàrberi, Reference Bàrberi2002; Bond and Grundy Reference Bond and Grundy2001). For organic horticultural and fruit crop production, polyethylene (PE) mulches are widely used because of their durability, flexibility, and excellent weed suppression (Espí et al. Reference Espí, Salmerón, Fontecha, García and Real2006). PE mulches suppress weeds by blocking sunlight, reducing seed germination, and serving as a physical barrier to weed growth (Iqbal et al. Reference Iqbal, Raza, Valipour, Saleem, Zaheer, Ahmad, Toleikiene, Haider, Usman and Nazar2020). Additionally, they provide a favorable environment for crop plant growth (Kasirajan and Ngouajio Reference Kasirajan and Ngouajio2012; Lamont Reference Lamont and Orzolek2017; Tarara Reference Tarara2000). Benefits include soil temperature modification, soil moisture retention, soil structure improvement, microbiota activity enhancement, and in some cases, insect pest suppression (Iqbal et al. Reference Iqbal, Raza, Valipour, Saleem, Zaheer, Ahmad, Toleikiene, Haider, Usman and Nazar2020; Kasirajan and Ngouajio Reference Kasirajan and Ngouajio2012; Ngosong et al. Reference Ngosong, Okolle and Tening2019).

PE mulches are made primarily from low-density PE, a nonbiodegradable petroleum-based material (Kader et al. Reference Kader, Senge, Mojid and Ito2017; Kasirajan and Ngouajio Reference Kasirajan and Ngouajio2012). Widespread use of PE mulches is increasing plastic pollution in agricultural soils, with an estimated global usage of 40 billion kilograms per year (Khalid et al. Reference Khalid, Aqeel, Noman and Rizvi2023; Mormile et al. Reference Mormile, Stahl, Malinconico and Malinconico2017). PE mulch fragments often accumulate in soils, landfills, and aquatic environments (Barnes et al. Reference Barnes, Galgani, Thompson and Barlaz2009) and tend to break into microplastics (<5 mm) after photo-oxidative reactions (Singh and Sharma Reference Singh and Sharma2008). These small fragments have been shown to bioaccumulate in various organisms and consequently enter food chains, with unknown consequences for human health (Bhuyan Reference Bhuyan2022). Other disadvantages include complex recycling or disposal processes that require removing soil particles, plant residues, and agrochemicals that may contaminate the PE mulches (Dong et al. Reference Dong, Yang, Zhang, Yang, Wang and Zhou2022; Serrano-Ruiz et al. Reference Serrano-Ruiz, Martin-Closas and Pelacho2021). The expense and labor associated with mulch removal, recycling, and disposal can also substantially increase production costs (Velandia et al. Reference Velandia, Smith, Wszelaki, Galinato and Marsh2018).

To address the negative impacts of PE mulches, biodegradable mulch films have been developed as potential alternatives (DeVetter et al. Reference DeVetter, Zhang, Ghimire, Watkinson and Miles2017; Serrano-Ruiz et al. Reference Serrano-Ruiz, Martin-Closas and Pelacho2021; Wang et al. Reference Wang, Shrestha, Tymon, Zhang, Miles and DeVetter2022; Weber Reference Weber2003). However, none are allowed in U.S. organic production because they are not 100% biobased and cannot biodegrade by at least 90% within 2 yr or less, in accordance with U.S. Department of Agriculture National Organic Program standards (7 CFR 205.601) (USDA-AMS 2015). Other biodegradable mulch products are permitted for organic farming, such as paper sheet mulches, but these lack durability when exposed to windy and wet conditions (Weber Reference Weber2003).

One alternative mulch that can address these shortcomings is cellulose-based hydromulch (HM), of which multiple formulations are in development (Ahmad et al. Reference Ahmad, DeVetter, McFadden, Maupin, Bajwa, Durado, Weyers, Galinato, Weiss and Gramig2024; Claramunt et al. Reference Claramunt, Mas, Pardo, Cirujeda and Verdu2020; Durado et al. Reference Durado, Bajwa, Gramig, Weyers, DeVetter, Formiga and Galinato2024). HMs are applied in a liquid phase and poured or sprayed onto the soil surface (Warnick et al. Reference Warnick, Chase, Rosskopf, Scholberg, Simonne, Koenig and Roe2006b) and have been studied as a weed control strategy, with positive results in crops such as artichoke (Cynara cardunculus L.), escarole (Cichorium endivia L.), muskmelon (Cucumis melo L.), and bell pepper (Capsicum annuum L.) (López-Marín et al. Reference López-Marín, Romero-Muñoz, Gálvez, del Amor, Piñero and Brotons-Martínez2021; Romero-Muñoz et al. Reference Romero-Muñoz, Albacete, Gálvez, Piñero, del Amor and López-Marín2022; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a). However, research comparing HMs to PE and paper mulches for weed suppression efficacy in other transplanted annual horticultural production systems is lacking.

Strawberry cropping systems, both organic and conventional, are potential systems within which HMs might be implemented because production relies on PE mulches to control weeds and protect yields in the United States and globally (Lantz et al. Reference Lantz, Swartz, Demchak and Frick2010). The physical properties of PE mulches and their effects on this crop have been extensively studied, especially effects of PE color on the quantity and quality of light reaching the crop canopy (Johnson and Fennimore Reference Johnson and Fennimore2005; Kasperbauer Reference Kasperbauer2000) and the role of mulch color in regulating soil temperature (Pandey et al. Reference Pandey, Singh and Maurya2015). Strawberry root physiology and development are highly sensitive to extreme soil temperatures, which vary geographically (Ganmore-Neumann and Kafkafi Reference Ganmore-Neumann and Kafkafi1985; Gonzalez-Fuentes et al. Reference Gonzalez-Fuentes, Shackel, Lieth, Albornoz, Benavides-Mendoza and Evans2016). Mulches can be used to regulate soil temperature (e.g., black PE mulches can increase the soil temperature in a range of 5.3 to 6.1 C, whereas white and white-on-black PE mulches can increase soil temperature from 2.2 to 4 C compared to bare soil) (Heißner et al. Reference Heißner, Schmidt and von Elsner2005; Ibarra-Jiménez et al. Reference Ibarra-Jiménez, Zermeño-González, Munguía-López, Quezada-Martín and De La Rosa-Ibarra2008).

However, it is unknown whether the addition of coloring substances to HMs could provide soil microclimatic modifications similar to various PE mulch colors. Some HM formulations that use colorants have been explored with the aim of reducing weed germination and growth (Caputo et al. Reference Caputo, Di Cesare, Iovieno, Immirzi, Baldantoni, Stipic, Zaccardelli and Venezia2024) or to modify light reflection for insect pest management (Liburd et al. Reference Liburd, Casagrande and Alm1998). Most research on use of HMs for agricultural purposes has focused on developing effective formulations and testing various HM rates (i.e., the amount of HM applied per unit land area) in multiple cropping systems (Ahmad et al. Reference Ahmad, DeVetter, McFadden, Maupin, Bajwa, Durado, Weyers, Galinato, Weiss and Gramig2024; Claramunt et al. Reference Claramunt, Mas, Pardo, Cirujeda and Verdu2020; Gloeb et al. Reference Gloeb, Irmak, Isom, Lindquist and Wortman2023; Mas et al. Reference Mas, Pardo, Pueyo, Verdú and Cirujeda2021; Puka-Beals and Gramig Reference Puka-Beals and Gramig2021). However, HM field performance has not been widely explored, especially for HM formulations that contain colorants. To maximize the benefits of HMs in horticultural crop production, especially in organic strawberry, researchers and practitioners need to understand whether HMs that vary in rate and color would affect weed control and basic microclimatic variables that may impact yield and fruit quality.

Therefore, the objectives of this study were to 1) evaluate the weed suppression efficacy, fruit yield, and fruit quality associated with HMs varying in color (dark and light) and rate (low and high) in an annual strawberry production system; and 2) quantify how HM color (dark and light) and rate (low and high) influence soil and air temperature and soil volumetric water content (VWC). Understanding these responses will benefit organic strawberry producers seeking sustainable biodegradable mulching alternatives. The following hypotheses were tested: 1) HMs, regardless of color, will physically suppress seedling emergence, achieving weed density and weed biomass reduction comparable to PE or paper sheet mulches; 2) strawberry yield and fruit quality will not differ between HMs and PE mulch.

Materials and Methods

Site Description and Experimental Design

Field experiments were conducted on certified organic land at the North Dakota State University Horticulture Research Farm near Absaraka (46.98845°N, 97.352303°W), and research field plots at the North Dakota State University main campus at Fargo (46.894806°N, 96.812075°W), in 2023. The soil at Absaraka is an Oxyaquic Hapludolls, with sandy loam texture, moderately well-drained, and slopes between 0% and 3% (USDA-NRCS 2000). At Fargo, the soil is a Typic Epiaquerts with clay texture, poorly to very poorly drained, and slopes between 0% and 1% (USDA-NRCS 2016).

The experimental design was a randomized complete block with four replications and eight treatments: 1) weedy check (no mulch, no weed management); 2) biochar-darkened HM low rate (HM-DL); 3) light HM low rate (HM-LL); 4) biochar-darkened HM high rate (HM-DH); 5) light HM high rate (HM-LH); 6) cellulose-based commercial paper mulch (PAP) (0.01 mm thick, WeedGuard Plus, Aurora, CO); 7) white-on-black low-density PE plastic mulch (0.03 mm thick, LECO Industries Inc. Saint Laurent, QC, Canada); and 8) weed-free check (no mulch, hand weeding). The low and high HM rates were approximately 5,800 and 8,700 kg dry matter ha−1. Addition of biochar powder resulted in a gray-colored mulch (i.e., dark), whereas the untinted mulch was white (i.e., light colored).

Field Preparation

In September 2022, prior to tillage, eight 2-cm-diam soil sample cores were removed with a soil probe at 0 to 15.2 cm and 15.2 to 30.5 cm in a zigzag pattern across each experimental block and composited to obtain one sample at each soil depth to determine the amount of fertilizer to apply before transplant. At Fargo, the tillage consisted of three rototiller passes (655 rotary hoe; John Deere, Moline IL), two chisel plow passes (3000; Case IH, Racine, WI) at 7.6-cm and 15.2-cm depths, followed by two additional rototiller passes. At Absaraka, two rototiller passes were adequate to prepare the soil. Granular NPK fertilizer (2-4-3 Chick-N-Poo; Pearl Valley Farms, Pearl City, IL) was broadcast by hand, achieving an application rate of 67 kg N ha−1 (Klodd et al. Reference Klodd, Rosen and Tepe2021), then incorporated with the John Deere 655 rotary hoe (September 7, 2022, at Abraska; September 26, 2022, at Fargo). On the same day, raised beds (36.6 m × 0.8 m) were built and covered with black PE mulch (0.03 mm thick) using a tractor-pulled bed shaper (MRB-448; Nolt’s LLC, Shippensburg, PA). Simultaneously, a drip irrigation line (1.6 cm diam, emitter spacing 10.2 cm) (Dripworks, Willits, CA) was buried 19.8 cm deep in the center of each raised bed. We initially covered all the raised beds with PE mulch for the winter to facilitate spring planting and HM application in 2023. The field sites are poorly drained with heavy soils, and spring weather is generally wet, delaying spring field operations, especially those involving soil disturbance. By building the beds in the fall, spring planting delays were reduced, but mulch coverage was needed to prevent weed emergence before treatments were established. This approach helped address research- and location-specific constraints and was not meant to reflect recommended grower practices.

Treatment Application

Black PE mulch covering beds was removed in spring 2023, then the raised beds (i.e., blocks) were each divided into eight plots of 4.6 m × 0.9 m to which treatments were randomly assigned. Commercial paper mulch and white-on-black PE mulch were installed manually and secured by covering mulch edges with soil. To prepare HM treatments, newsprint rolls (ULINE, Pleasant Prairie, WI) were cut with an office paper shredder (EverShred c149-d; Bonsaii, Flowery Branch, GA) into fragments of approximately 1.5 cm × 0.5 cm. This paper was used as a lignocellulosic HM base material and mixed at a concentration of 39.6 kg paper dry matter per m3 of tap water, along with guar gum (Mountain Rose Herbs, Eugene, OR) added as a tackifier at 6% HM total dry mass. For the dark-colored HM treatments, powdered biochar (Biochar Now, Berthoud, CO) was incorporated at 20% of HM total dry mass.

The HM slurries were mixed using a water pump 5.1 cm × 5.1 cm, with engine capacity of 205 cm3 powered by 4,780 W (Vanguard; Briggs & Stratton, Wauwatosa, WI), until cohesive and smooth and contained in a 0.2-m3 plastic tank. Slurries were then applied to experimental units using a 2.5-cm hose with an exit brass nozzle of 1.9 mm diam (80400-M; Turbo Turf Technologies Inc., Beaver Falls, PA) attached to a less powerful, clearwater pump 2.5 cm × 2.5 cm, with an engine capacity of 79 cm3 (60729-M Ironton; Northern Tool & Equipment Co., Burnsville, MN). The pumps, mixing tank, and nozzle were mounted on a wooden platform attached to a tractor (750 Series-15 Kw; John Deere, Moline, IL) (Figure 1A). HM slurry flow was set at 1.4 L s−1, application speed was 1.0 km h−1, and the nozzle was placed 54.9 cm from the raised bed surface. Two and three HM application passes were necessary to achieve the low and high rate, respectively. After the first HM pass was sprayed and allowed to dry, the second and third passes were applied the following day.

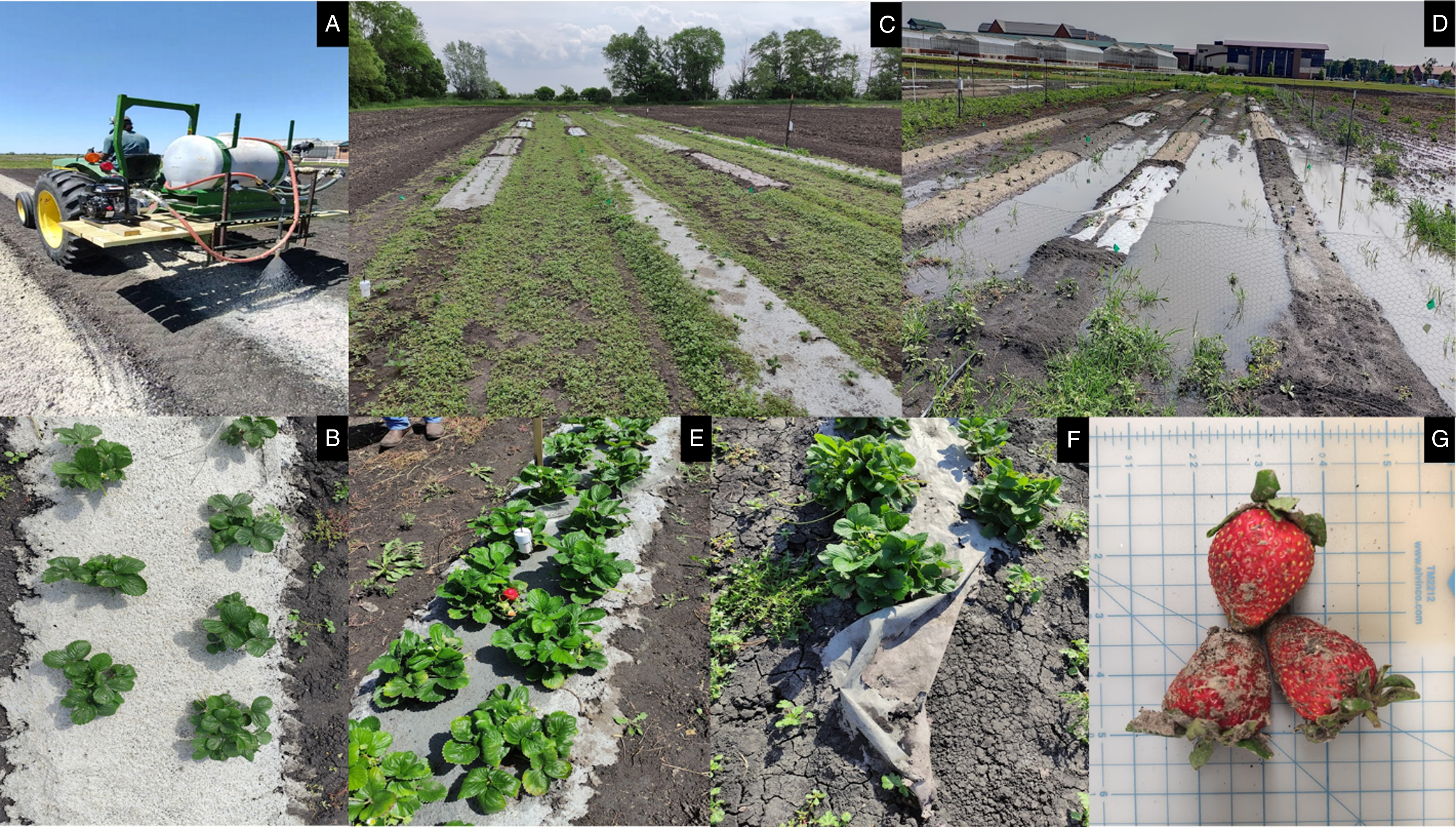

Figure 1. (A) Hydromulch (HM) application machine. (B) Weed suppression by light HM high rate (HM-LH) treatment at Fargo, ND (July 10, 2023). (C) High common purslane density in plant rows and alleyways at Absaraka, 2 wk after transplanting. (D) Flooding at Fargo from rainfall (August 23 and 24, 2023). (E) HM-LH at harvest (August 14, 2023) in Absaraka. (F) Commercial paper sheet torn by winds at Fargo (September 1, 2023). (G) Paper fibers adhered to harvested fruit after rain (August 13, 2023) at Fargo.

Before transplanting, strawberry plants (Albion cultivar; Indiana Berry & Plant Co., Plymouth, IN) were stored in a dark refrigerator at 2 C for 2 wk to maintain dormancy after delivery. One day before transplanting, plants were trimmed by cutting fully expanded old leaves, leaving young leaves emerging from the crown and 15.2 cm of root length. Plant roots were kept in totes with tap water and acclimated in a greenhouse for 24 h. Approximately 2 h after spraying the last HM pass, 17 strawberry plants were planted per plot (Absaraka: June 2, 2023; Fargo: June 8, 2023), leaving a 0.8-m buffer at each end, in an alternate double-row arrangement separated by 54.4 cm, with each row 17.8 cm away from the bed edge and 38.1 cm within-row spacing between plants. A flat steel bar was used to insert the roots through the HM or PE mulch and into the soil, placing the strawberry crown level with the soil surface (Lantz et al. Reference Lantz, Swartz, Demchak and Frick2010). This method resulted in minimal mulch disturbance, leaving a small hole through which plants could emerge.

Crop Management

Irrigation was applied when soil water content was between 20% and 25%, according to sensor readings. Organic NPK liquid fertilizer (4-2-2 fish emulsion; TRUE Organic Products Inc., Spreckels, CA) was fertigated using an injector operated at 0.1 MPa (1 Gal EZ-FLO; EZ-FLO Injection Systems, Rocklin, CA), targeting 22.4 kg ha−1 per month (Klodd et al. Reference Klodd, Rosen and Tepe2021). Weeds growing in alleyways between beds were removed mechanically every 3 wk with a power harrow of 81.3 cm (921PH320; BCS America, Oregon City, OR) attached to a two-wheel tractor (model 749; BCS America). Weeds growing on bed edges and planting holes were removed by hand every 2 wk. The weed-free check was hand-weeded every week. No insect pest management tactics were used to allow for assessment of treatments effects on pest and beneficial arthropod populations for another study.

Data Collection

During May 2023, soil moisture and temperature sensors (TEROS-11; Meter Group, Pullman, WA) were installed in each treatment in one block at Fargo and Absaraka. Sensors were installed equidistant between two strawberry plants 15.2 cm deep and connected to dataloggers (Zentra Zl6; Meter Group) to record soil temperature and volumetric water content (measurements were logged each hour). Air temperature sensors (HOBO UA 002-64; Onset, Bourne, MA) were hung on a curved steel bar 0.5 mm diameter and installed approximately 5.1 cm above the ground surface in between two plants in each treatment of one replication. These were covered with a piece of white PVC pipe 3.8 cm in diameter, closed on the top with a PVC lid to prevent direct solar radiation, but opened at the bottom to allow air circulation.

Weeds that penetrated mulches were not removed and were counted using a quadrat of 0.5 m × 0.5 m placed in two randomly chosen locations in each plot. Weeds were counted by species at two sampling periods, nondestructively at 1) peak weed emergence (PWE) (Absaraka: June 27, 2023; Fargo: July 17, 2023), defined as the time at which most early summer annual weeds had emerged and developed at least four true leaves; and destructively at 2) peak weed vegetative growth (PWVG) (Absaraka: August 8, 2023; Fargo: August 18, 2023), defined as the time when most summer annual weed species were entering reproductive phase. At PWVG, weed populations were sampled destructively to estimate weed shoot dry biomass by cutting weeds at the soil surface. Plants were placed into paper bags and kept in a drying chamber at 70 C for 2 wk; dry biomass was measured using a digital scale (Entris II BCE622-1S; Sartorius, Göttingen, Germany).

At harvest (August 8 to October 11, 2023), strawberry fruit was picked by hand at maturity, usually once or twice a week. Fruit was counted and weighed and graded into marketable and nonmarketable. Total yield consists of marketable plus nonmarketable. Yield was expressed on a per-plant basis to account for plots where plants died (no treatment effect was noted regarding plant death). Fruit length and width were assessed with a digital caliper (CD-6ASX; Mitutoyo, Aurora, IL) for 20 arbitrarily chosen fruit per plot. A subsample of three ripened fruit per plot was frozen until processed for quality assessments, then the fruit was crushed manually, and the fruit juice was collected in a petri dish. Brix and pH were measured with a digital refractometer (MA871; Milwaukee Instruments, Rocky Mount, NC) and pH meter (PAL-pH; ATAGO Co., Tokyo, Japan), respectively, using 1-mL aliquots of the juice for each.

Data Analyses

Analysis of variance was used to compare treatment means by generalized linear mixed models using the GLIMMIX procedure with SAS software (v.9.4; SAS Institute Inc., Cary, NC) using the distribution that produced the best model fit. Pairwise differences among means were compared using Tukey’s HSD. Significance was tested at P ≤ 0.05. Treatment and location were considered fixed effects; replication was a random effect nested within location. If interactions between treatment and location occurred, the slice option in the lsmeans statement was used to evaluate the effect of treatment within each location and the effect of location within each treatment separately and using Tukey’s HSD correction for multiple comparisons. For the response variables weed biomass and weed density, confidence intervals were used to compare other mulch treatments against PE mulch due to the lack of variance associated with this treatment (which usually contained zero weeds in every plot). If the confidence interval associated with a mulch treatment included zero, then PE mulch was considered not significantly different from that treatment. Fruit length and width were used to calculate fruit volume (cm3); that is, volume of a square pyramid = (1/3) × (width)2 × (length). Hourly sensor data (i.e., air and soil temperature, soil VWC) were converted to averages per day using MATLAB software (v.r2023b; MATLAB, Natick, MA); however, no statistical analysis was performed because sensor data were collected from just one replicate at each location.

Results and Discussion

Microclimate

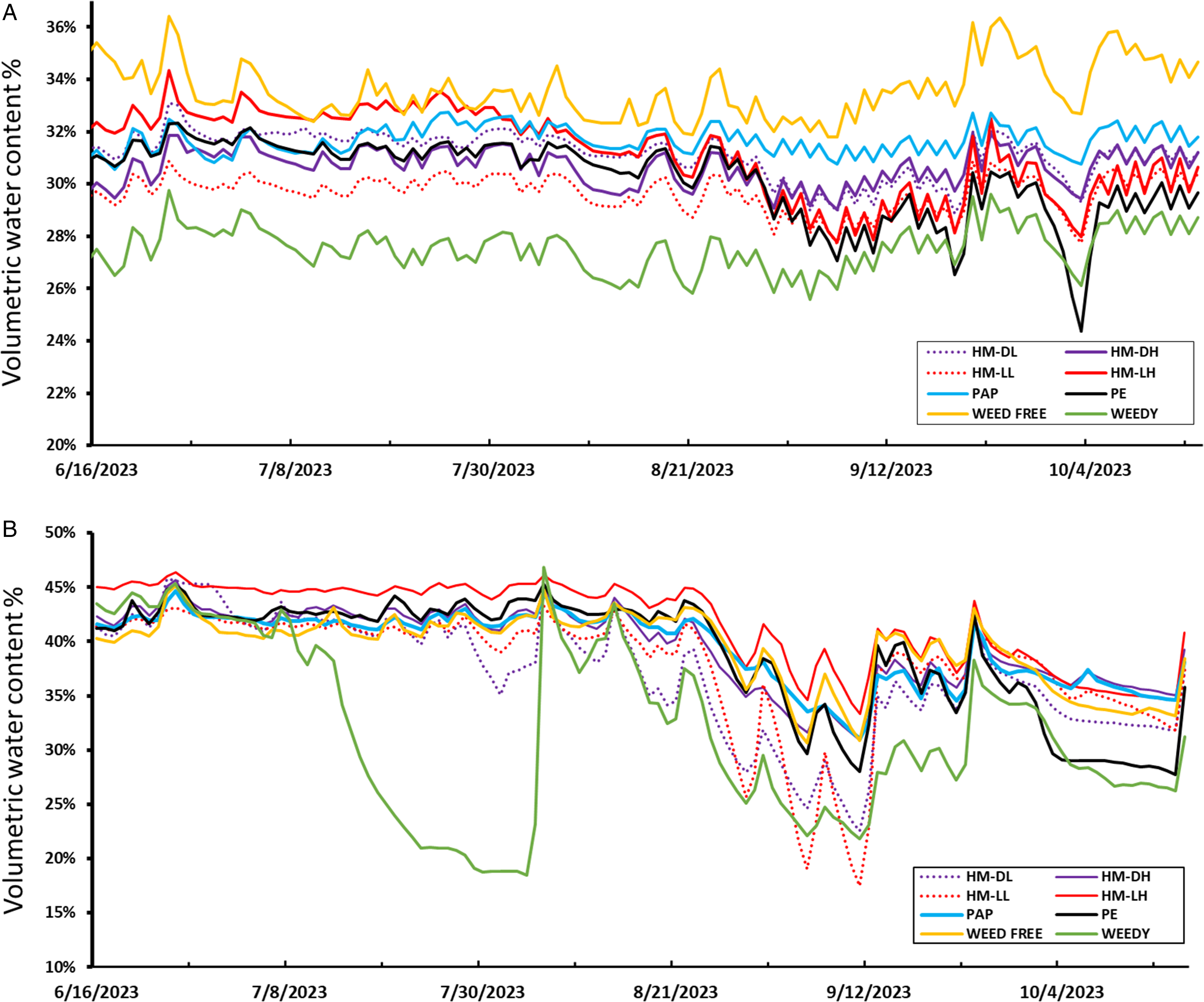

The microclimatic variables VWC and soil temperature were measured in only one replication; therefore, statements about these variables are not based on statistical results but help to give context to other results, analogous to weather station data. At both locations, the highest average daily soil temperatures were recorded with PE mulch and the weed-free check treatments. Soil temperatures were on average 1.6 C lower under all HMs compared to that under PE mulch (Figure 2). Daily average air temperature proximal to the mulch surfaces did not differ substantially among mulch treatments in either location (data not shown). At Absaraka, soil VWC associated with mulch treatments ranged from 24% to 36% across the growing season. HMs were associated with an approximate 2% variation in soil VWC over the growing season (Figure 3A). At Fargo, during the first two field season months, soil VWC in all the treatments was above 40%. From July onward, plots with low-rate HMs generally had lower soil moisture compared with plots with high-rate HMs, regardless of color. One month after crop establishment, soil VWC associated with the weedy check fell to less than 20%, likely due to large water consumption by weeds during peak vegetative growth and/or contact failure between the sensor and the soil due to cracking; by August 5, 2023, the soil VWC returned to values that were similar to all other treatments due to rainfall (Figure 3B).

Figure 2. Average daily soil temperature measured at 15.2 cm deep at (A) Absaraka and (B) Fargo, measured in one mulch treatment replication. Abbreviations: WEEDY, weedy check; HM-LL, light HM low rate; HM-DL, dark HM low rate; HM-LH, light HM high rate; HM-DH, dark HM high rate; PAP, cellulose-based commercial paper mulch; and PE, white-on-black polyethylene (PE) plastic mulch.

Figure 3. Average daily soil volumetric water content (%) measured at 15.2 cm deep at (A) Absaraka and (B) Fargo in one mulch treatment replication. See Figure 2 for abbreviations.

Weed Density Response to Mulch Treatments

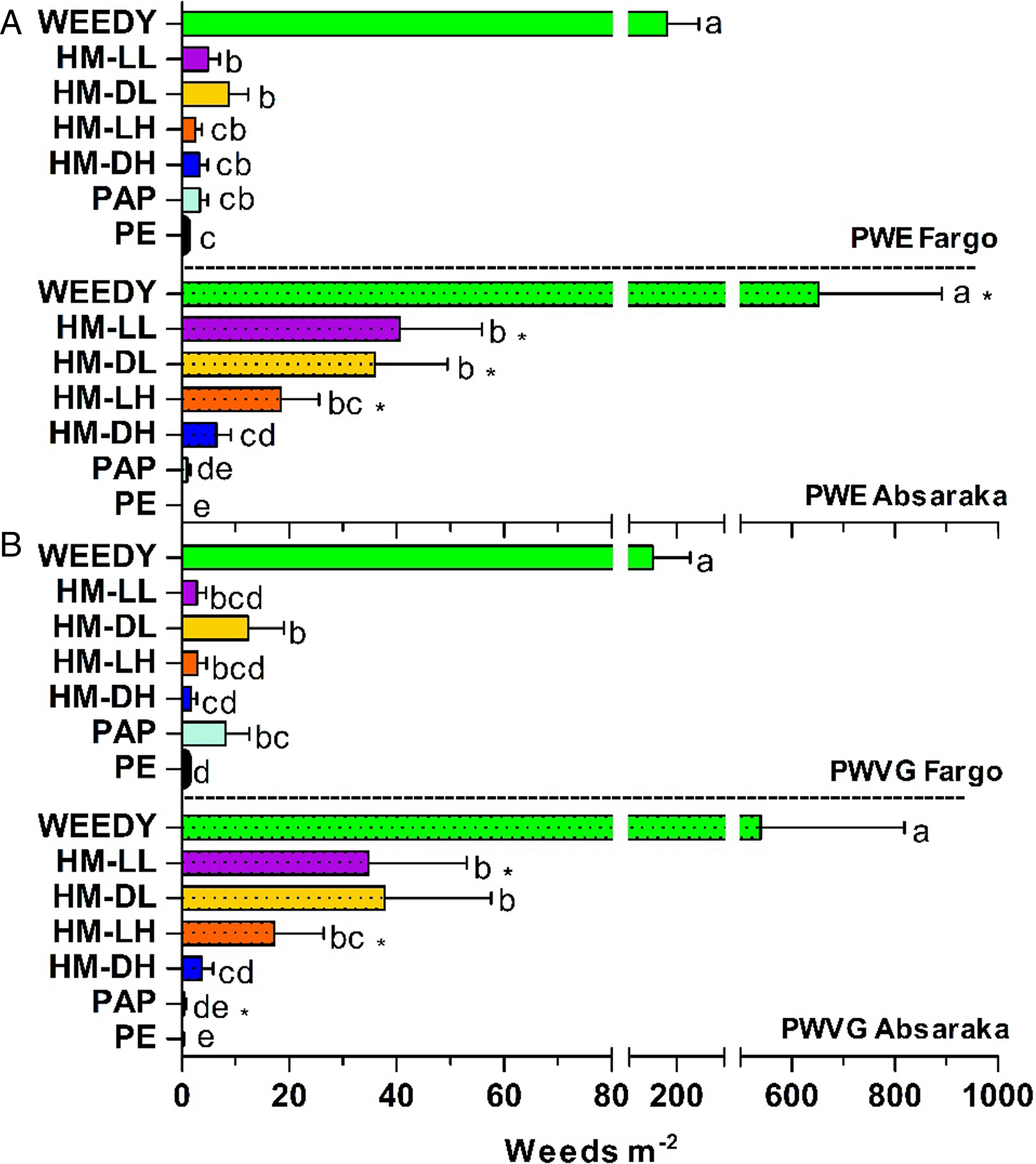

At Fargo, the predominant weed species was Venice mallow, and at Absaraka, common purslane dominated. Weed density responses during both sampling periods were analyzed separately by location due to mulch treatment × location interactions (PWE, P = 0.0097; PWVG, P = 0.0007) (Figure 4). At PWE, weed density in weedy checks differed between locations, with Absaraka having higher weed density than Fargo (P = 0.0189; 652 vs. 181 plants m−2 at the Absaraka and Fargo locations, respectively). At Fargo, during PWE, weed density suppression provided by HM-LH and HM-DH treatments did not differ from that of the PE mulch (3 and 3 vs. 0 plants m−2, respectively) (Figure 4A). Low-rate HM treatments (HM-LL and HM-DL) resulted in higher weed densities than PE mulch (5 and 9 vs. 0 plants m−2) but did not differ from high-rate HM treatments (HM-LH and HM-DH). The PAP treatment was associated with low weed densities (3 plants m−2) that did not differ from HMs treatments or PE mulch (Figure 4A). At Absaraka, all HM treatments resulted in higher weed densities compared to PE but had fewer weeds than the weedy check. Moreover, weed density for low-rate HM treatments (HM-DL and HM-LL) (36 and 41 plants m−2, respectively) performed poorly against high-rate HM treatments (6 and 18 plants m−2); however, HM-LH was not different from HMs treatments with the low rate. PAP mulch provided excellent weed suppression (1 plant m−2), which did not differ from HM-DH and PE (6 vs. 0 plants m−2) (Figure 4A).

At PWVG at Fargo, weed density did not differ among HM-LL, HM-LH, HM-DH, and PE mulch treatments (3, 2, 3, and 0 plants m−2, respectively), with only the HM-DL treatment having a higher weed density (17 plants m−2) than PE (Figure 4B). At Absaraka, weed density was higher for the low-rate HM treatments (HM-LL and HM-DL, 35 and 38 plants m−2, respectively) compared to HM-DH, PAP, and PE (4, 0 and 0 plants m−2, respectively) (Figure 4B). Overall, weed density was lower in HMs compared with the weedy check, regardless of HM color or rate.

Figure 4. Mean + standard error of the mean for effects of mulch type on weed density (plants m−2) quantified at (A) peak weed emergence (PWE) and (B) peak weed vegetative growth (PWVG) at Absaraka and Fargo. Lower-case letters denote differences among mulch treatments within a location. Bars accompanied by an asterisk (*) denote treatment differences between locations within a mulch treatment according to Tukey’s HSD (α = 0.05). See Figure 2 for abbreviations.

Weed density reduction has been reported with various HM formulations (Ahmad et al. Reference Ahmad, DeVetter, McFadden, Maupin, Bajwa, Durado, Weyers, Galinato, Weiss and Gramig2024; Claramunt et al. Reference Claramunt, Mas, Pardo, Cirujeda and Verdu2020; Mas et al. Reference Mas, Pardo, Pueyo, Verdú and Cirujeda2021; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a). In our study, the high-rate HMs were associated with relatively low weed densities (<20 plants m²) during both sampling periods at both locations. Additionally, at Fargo the weed density in the high-rate HMs treatments did not differ from the complete weed suppression provided by PE mulch (Figure 4B). Our study did not focus on identifying or quantifying the mechanisms underlying weed suppression. However, previous research has shown that HMs can reduce weed emergence either by reducing seed germination via light-mediated dormancy responses or by physically impeding the emergence of germinated seedlings (Claramunt et al. Reference Claramunt, Mas, Pardo, Cirujeda and Verdu2020; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a).

At Absaraka, weed density in all HMs were greater than those in PE mulch; furthermore, the low-rate HMs suppressed weed emergence less effectively than high-rate HMs (Figure 4B). A lower HM rate results in a thinner layer that is more likely to be penetrated by seedlings, which agrees with findings reported by Gloeb et al. (Reference Gloeb, Irmak, Isom, Lindquist and Wortman2023). In our study, common purslane and Canada thistle (Cirsium arvense L.) were the weed species that most frequently grew through HMs. Overall, the dominant weed species was common purslane, which germinated prolifically on raised bed edges where HM layers were often discontinuous and thinner and then encroached into strawberry rows (Figure 1C). Canada thistle easily penetrated HMs via sharp rhizome apices. The rhizomes have large energy reserves and can grow substantially without light (McAllister and Haderlie Reference McAllister and Haderlie1985). The varying efficacy of HMs to control other perennial weeds such as purple nutsedge (Cyperus rotundus L.) has been previously reported (Mas et al. Reference Mas, Pardo, Pueyo, Verdú and Cirujeda2021, Reference Mas, Verdú, Pardo, Pueyo, Claramunt and Cirujeda2024; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a).

Mulch degradation over time also negatively affected weed density, especially late-emerging weeds (Immirzi et al. Reference Immirzi, Santagata, Vox and Schettini2009). Two factors potentially increased the deterioration of HMs at Absaraka. Soil physical properties can impact HM surface integrity in the presence of water, such as soil plasticity, which allows soils to resist deformations without cracking or disaggregating (Campbell Reference Campbell, Smith and Mullins2000). Sandy soils at Absaraka likely have a low plasticity index (Keller and Dexter Reference Keller and Dexter2012), which may have led to more cracking with soil drying. Clay soils at Fargo likely have greater plasticity and may have resisted cracking because of enhanced moisture retention; therefore, the HMs applied to clay soils may have cracked less. Testing HMs across various soil types and moisture levels would be important future steps to better understand the field performance of various HM formulations across a range of soils with varying physical properties.

Slight rainfall (4.6 mm) occurred shortly after the HM application at Absaraka, which likely weakened the HMs by washing away some mulch material before it was sufficiently dry, thus leading to increased HM cracking and subsequent weed emergence. Another major vulnerability of HMs is strength loss upon wetting, which reduces resistance to weed penetration (Liburd et al. Reference Liburd, Casagrande and Alm1998; Mas et al. Reference Mas, Verdú, Pardo, Pueyo, Claramunt and Cirujeda2024; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a). However, weed suppression by HMs at the Fargo location was unaffected by two heavy rain events (July 23 and 24, 2023 [65.7 mm], and August 5, 2023 [88.9 mm]), which flooded plots for multiple days (Figure 1D). It may be that the clay soil and a previously well-dried HM layer improved the mulch adhesion to the soil surface, thereby reducing the HM displacement risk. After rain, HM layers usually dried and recovered rigidity after 6 to 10 h with temperature >20 C, full sun, wind, and no clouds. Our observations suggest that rain is much more damaging to HMs if it occurs shortly after HM application, before the HM has dried. Further tests are required to study HM soil adhesion and degradation related to rainfall timing and extent.

Using powdered biochar as a colorant did not appear to affect the physical weed control effectiveness of HM, similar to that reported by Caputo et al. (Reference Caputo, Di Cesare, Iovieno, Immirzi, Baldantoni, Stipic, Zaccardelli and Venezia2024), who found no effect on weed density or biomass with a charcoal + galactomannan HM vs. galactomannan HM alone. Results from this study indicate that HM rate and inclusion of a tackifier (e.g., guar gum) are more important for weed suppression than darkening the HM with biochar and is similar to reports from previous research (Ahmad et al. Reference Ahmad, DeVetter, McFadden, Maupin, Bajwa, Durado, Weyers, Galinato, Weiss and Gramig2024; Durado et al. Reference Durado, Bajwa, Gramig, Weyers, DeVetter, Formiga and Galinato2024; Gloeb et al. Reference Gloeb, Irmak, Isom, Lindquist and Wortman2023). However, in 2022 preliminary field trials (unpublished data) wherein the HM was colored with powdered activated charcoal without guar gum, the weed densities for light and charcoal-dark HMs were 211 to 275 vs. 401 to 473 plants m−2, respectively. We speculate that adding activated charcoal increased HM microporosity and available spaces for seedling penetration due to its high specific surface area (Díaz-Teran et al. Reference Díaz-Teran, Nevskaia, López-Peinado and Jerez2001; Yalçın and Sevinc Reference Yalçın and Sevinc2000). Therefore, the material used to color the HM may affect the physical properties of the HM and thus, physical weed suppression.

Commercial paper sheet mulches (PAP) have low tensile strength, which is a major drawback (Li et al. Reference Li, Zhang, Ren, Zhang and Zhang2021; Schonbeck Reference Schonbeck1999). At Fargo, weed suppressive ability associated with PAP decreased a month and a half after transplanting as sheets degraded along the wet bed edges, and winds (average maximum wind speed in May and June is 22 km h−1 [NDAWN 2023]) tore away mulch fragments, allowing late weed emergence (Figure 1A). In contrast, at Absaraka, rapid soil drainage allowed fast mulch drying, recovering rigid properties soon thereafter, and combined with wind protection provided by nearby trees, excellent weed control was provided by PAP for the entire growing season.

Weed Biomass Response to Mulch Treatments

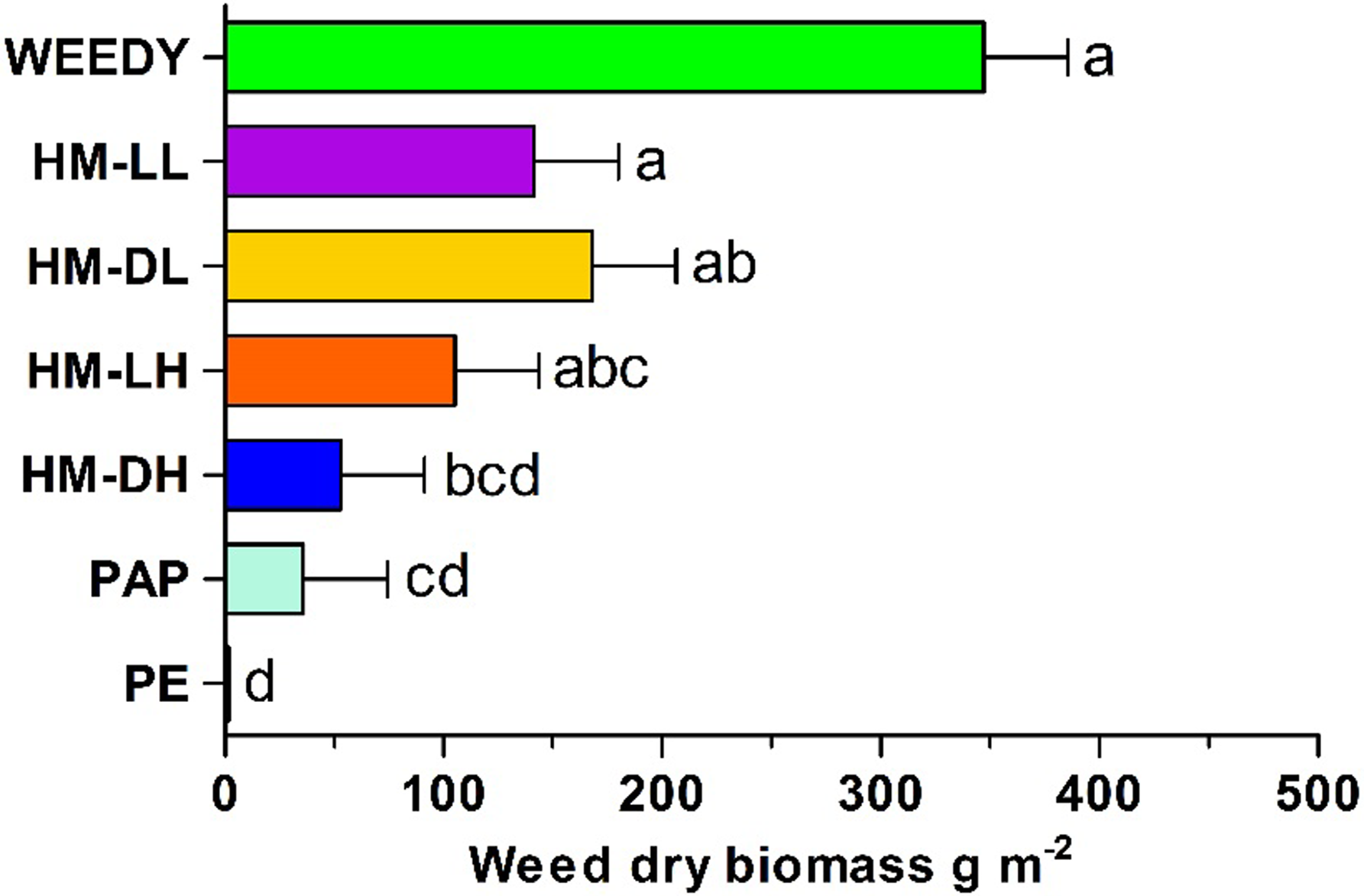

At PWVG, because the treatment by location interaction was not significant (P = 0.1154), the effect of the treatments was pooled by location (Figure 5). Weed biomass for HM-DL, HM-LL, and HM-LH treatments did not differ from that of the weedy check (168, 141, and 105 vs. 347 g m−2, respectively) because the few weeds that emerged through the HM layer grew without competition and produced substantial dry matter, comparable to the weedy check biomass, which included more but smaller individual weeds. Conversely, weed biomass with HM-DH and PAP mulches did not differ from that with the PE mulch (53, 36, and 0 g m−2, respectively) (Figure 5). High rates of HM led to relatively low weed biomass, reflecting effective weed suppression and is consistent with previous reports (Gloeb et al. Reference Gloeb, Irmak, Isom, Lindquist and Wortman2023; Puka-Beals and Gramig Reference Puka-Beals and Gramig2021). Overall, HMs can be a viable alternative to PE mulches for weed suppression, especially with higher application rates and effective tackifiers.

Figure 5. Mean + standard error of the mean weed biomass (g m−2) at peak weed vegetative growth (PWVG), for mulch treatments. Lower-case letters denote differences among treatment means within a location according to Tukey’s HSD (α = 0.05). See Figure 2 for abbreviations.

Crop Responses to Mulch Treatments

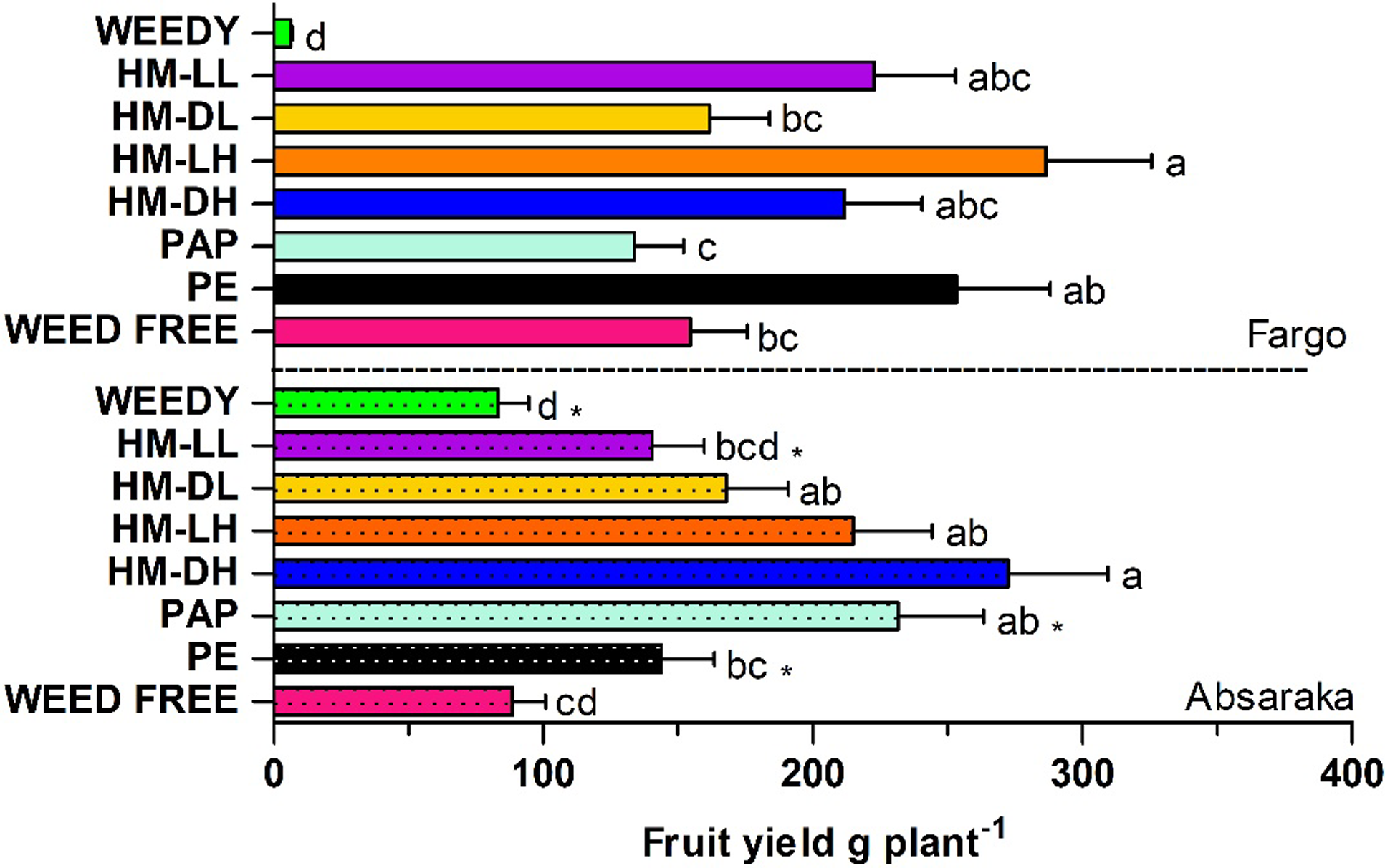

The effect of mulch treatments on total strawberry fruit yield were analyzed separately due to mulch treatment by location interactions (P ≤ 0.0001) (Figure 6). At Fargo, strawberry yields associated with all HM treatments were not different from the yield with the PE mulch, whereas PAP mulch yielded less than PE mulch (134 vs. 253 g plant−1). At Absaraka, HM-DH was the only treatment with greater yield than the PE mulch (272 vs. 144 g plant−1). Yields for other mulch treatments and the weed-free check were not different from yield with PE mulch (Figure 6).

At Fargo, fruit yield from the weedy check (6 g plant−1) was lower than yield from all the mulch treatments and the weed-free check. At Absaraka, the weedy check treatment produced poor yields (83 g plant−1) (Figure 6). However, those yields were not different from those associated with the weed-free check (89 g plant−1) (Figure 6). Additionally, the weed-free check was associated with lower yields compared with the highest-yielding treatment (68% less than HM-DH at Absaraka and 46% less than HM-LH at Fargo). This suggests that excellent weed control does not always lead to higher yields of strawberry, and possibly mulch-related environmental modifications benefit yield independently of weed presence.

Figure 6. Mean + standard error of the mean total fruit yield (g plant−1) at Absaraka and Fargo for mulch treatments. Lower-case letters denote differences among treatment means within location. Bars accompanied by an asterisk (*) denote differences between location means within a mulch treatment according to Tukey’s HSD (α = 0.05). See Figure 2 for abbreviations.

In our experiment, limited (i.e., not replicated) data suggest that HMs maintained soil VWC similarly to PE mulch. We speculate that HMs may have reduced soil surface water evaporation by isolating the soil from direct solar radiation and restricting water and vapor flow across the soil-atmosphere as suggested by prior studies (O’Brien et al. Reference O’Brien, Acharya, Alghamdi, Niaghi, Sanyal, Wirtz, Daigh and Desutter2018; Saglam et al. Reference Saglam, Sintim, Bary, Miles, Ghimire, Inglis and Flury2017 Shen and Zheng Reference Shen and Zheng2017; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a). Furthermore, the HM liquid phase containing dissolved guar gum may have moved into the soil surface, binding soil microaggregates, thereby increasing moisture retention. Jian et al. (Reference Jian, Guanghua, Ningning, Zhan-xiang, Xue, Shijie and Xiaole2018) demonstrated similar effects with biodegradable HMs mixed with polyvinyl alcohol and sodium carboxymethylcellulose tackifiers.

There was no abrupt change in the soil temperature pattern between the HM and PE mulches; in fact, all HMs were approximately 1.2 to 1.8 C cooler than the PE mulch throughout the season, which is consistent with previous research reports (Moreno et al. Reference Moreno, González-Mora, Villena and Moreno2023; O’Brien et al. Reference O’Brien, Acharya, Alghamdi, Niaghi, Sanyal, Wirtz, Daigh and Desutter2018; Warnick et al. Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a). These mulches may have buffered the rapid fluctuations between maximum and minimum temperatures as was suggested by Warnick et al. (Reference Warnick, Chase, Rosskopf, Simonne, Scholberg, Koenig and Roe2006a). HM color did not seem to affect the soil temperature, possibly because the dark gray coloration of the biochar was not as dark as colors that can be achieved with charcoal or inks (Caputo et al. Reference Caputo, Di Cesare, Iovieno, Immirzi, Baldantoni, Stipic, Zaccardelli and Venezia2024; Schettini et al., Reference Schettini, Vox, Malinconico, Immirzi and Santagata2004). We used biochar as a colorant because it was the only material that our organic certifiers would allow, but preliminary tests showed that activated charcoal produced a darker gray of HM.

Strawberry yield is a complex outcome influenced by various environmental variables such as soil and canopy temperature, humidity, CO2 concentration, plant nutrition, and light quality and quantity (Hidaka et al. Reference Hidaka, Dan, Imamura, Miyoshi, Takayama, Sameshima, Kitano and Okimura2013), interacting with plant traits such as crown size, leaf size, and flowering and production periods (Sim et al. Reference Sim, Kim, Ahn, Ahn and Kim2020). However, environmental modifications caused by mulching can affect the crop’s microclimate by modifying the soil thermal energy flux and light reflection patterns, and restricting soil water evaporation (Díaz-Pérez and Batal Reference Díaz-Pérez and Batal2002; Tarara Reference Tarara2000). DeVetter et al. (Reference DeVetter, Zhang, Ghimire, Watkinson and Miles2017) reported similar yield impacts on strawberries grown in bare soil compared to various commercial PE and biodegradable PAP mulches. Similarly, weed-free tomato plots produced lower yields compared to various PE mulches (Anzalone et al. Reference Anzalone, Cirujeda, Aibar, Pardo and Zaragoza2010).

Rajablariani et al. (Reference Rajablariani, Hassankhan and Rafezi2012) found tomato yields under black, white, clear, red, and silver/black PE mulches were greater (from 30,000 to 40,000 kg ha−1) than yields from weed-free checks (25 ton ha−1), and this was linked to increased lateral branches and leaves in plants grown with PE mulches, likely due to enhancing root-zone temperatures and soil moisture conservation, which led to an increase in root development and physiological processes in water and nutrient uptake (Díaz-Pérez and Batal Reference Díaz-Pérez and Batal2002; Kumar and Dey Reference Kumar and Dey2011).

The difference in fruit yield associated with the PE mulch treatment between locations could be related to variations in environmental factors. At Absaraka, lower soil VWC and higher average maximum daily soil and air temperatures than at Fargo may have influenced root development and impacted yield. Previous studies by Kuwagata et al. (Reference Kuwagata, Ishikawa-Sakurai, Hayashi, Nagasuga, Fukushi, Ahamed, Takasugi, Katsuhara and Murai-Hatano2012) and Nagel et al. (Reference Nagel, Kastenholz, Jahnke, Van Dusschoten, Aach, Mühlich, Truhn, Hanno, Terjung, Walter and Schurr2009) have shown these as critical factors affecting root growth and, consequently, crop yield. Wimmer et al. (Reference Wimmer, Klodd, Tepe and Hoover2023) recommend temperatures between 7.2 C and 29.4 C in Minnesota for optimal growth of day-neutral strawberries. Additionally, Palencia et al. (Reference Palencia, Martínez, Medina and López-Medina2013) found a nonlinear relationship between air temperature and strawberry yield, with greater yields occurring around 20 C. Peak soil temperatures for PE mulch at Absaraka regularly exceeded 30 C, potentially reducing yields, consistent with that reported by Durner et al. (Reference Durner, Barden, Himelrick and Poling1984), who found flowering inhibition in day-neutral cultivars at temperatures >30 C. Conversely, cooler soil and air temperatures at Fargo may have been more favorable for crop growth and fruit production, which agrees with a report by Ahmad et al. (Reference Ahmad, DeVetter, McFadden, Maupin, Bajwa, Durado, Weyers, Galinato, Weiss and Gramig2024) suggesting that a decrease in strawberry fruit yield associated with PE mulches was due to increased canopy air temperature caused by the black color of the mulch.

The strawberry fruit yield reduction from weed competition can be related to the amount of weed biomass, weed density, and competition timing (Pritts and Kelly Reference Pritts and Kelly2001), all of which are mediated by mulch presence. Weeds affect light quality and quantity for crop canopies differently depending on the species (Eaton et al. Reference Eaton, Feltner and Russ1973; Johnson and Fennimore Reference Johnson and Fennimore2005), which explains the varying yield among weedy check treatments between locations. At Fargo, poor crop yield (6 g fruit plant−1) might be attributed to the upright growth of Venice mallow, which covered the strawberry canopy. This reduced light quantity and the processes that depend on light, such as photosynthesis, light compensation point, or source-sink ratios can affect yield (Bazzaz and Carlson Reference Bazzaz and Carlson1982; Kasperbauer and Karan Reference Kasperbauer, Karan, Zamski and Schaffer2017). Conversely, at Absaraka, despite the high density of common purslane, strawberry plants grew taller than the weed canopy and yield from the weedy check did not differ from that of the weed-free check (83 vs. 89 g plant−1, respectively). This observation aligns with that reported by Ellis et al. (Reference Ellis, Guillard and Adams2000) who used common purslane as a living mulch in broccoli (Brassica oleracea L.) fields without any effect on yield. Its limited competitive ability can be attributed to its prostrate growth habit, which reduces its light competition ability; a small taproot minimizes competition for soil nutrients and water, and as a C4 plant able to switch to crassulacean acid metabolism under stress, common purslane is better suited to thrive in heat stress and drought rather than outcompeting crops in conditions with luxury water and nutrients (Koch and Kennedy Reference Koch and Kennedy1980).

Fruit Quality

HMs did not affect strawberry fruit quality (data not shown); pH values were 3.4 to 3.5, and Brix values ranged from 8.8 to 10.3 and were within normal values as reported previously (DeVetter et al. Reference DeVetter, Zhang, Ghimire, Watkinson and Miles2017; Samykanno et al. Reference Samykanno, Pang and Marriott2013; Scott et al. Reference Scott, Williams, Wallace and Du2021). Fruit dimensions and volume (14 to 19 cm3) were also not affected by HMs (data not shown). Mulching is also used to isolate strawberry fruit from direct soil contact; the latter may increase problems with fruit diseases and pest arthropods (Pires et al. Reference Pires, Folegatti, Tanaka, Passos, Ambrosano and Sakai2007). In dry conditions, HMs provide an effective barrier between the fruit and soil; however, under wet conditions, HMs can stay moist for hours or days, possibly increasing the exposure to diseases. Another drawback observed was that HM paper fibers sometimes adhered to fruit after heavy rains (Figure 1G), which may affect the fresh fruit marketability or complicate postharvest processing.

Practical Implications

HMs demonstrated promising effects on soil temperature regulation, soil VWC retention, and weed density reduction, despite site variations in HM performance. HMs applied at high rates with guar gum as a tackifier generally performed close to PE mulch or similarly to it in terms of weed density, regardless of the color. However, three or even two HM passes may not be feasible for commercial farms because of the high cost, and time and labor required, so a better application methodology is needed to apply an effective HM layer in one pass. Future studies should address HM layer degradation influenced by rainfall timing after the application, HM performance related to soil type, and cumulative effects on soils after using HM for multiple seasons. In general, even though only high-rate HMs at Fargo suppressed weeds equally to PE, all HMs were associated with strawberry yields that were comparable to yields with PE mulch, suggesting that HM could be a sustainable alternative to PE mulches. The microclimatic modifications provided by HMs may also be an advantage for strawberry and other horticultural crops exposed to more extreme environmental variation that is expected in association with climate change.

The cost of using HMs compared to PE mulch should be considered. Due to the small scale and the need to meet organic product certification standards for this research the cost of HM materials was greater than PE mulch for our experiment (from US$30,918 ha−1 to US$46,376 ha−1 vs. approximately US$1,450 ha−1). Less expensive cellulose sources and tackifiers can be used to reduce costs (i.e., economies of scale would reduce material costs). Commerical hydromulch products exist (e.g., produced by Profile Products LLC, Buffalo Grove, IL) that would substantially lower the cost of HM application, but these products could not be used because they contain colorants and contaminants that are typically not allowed in organic production. Furthermore, greater HM material costs can be offset by considering reduced additional expenses associated with disposal and transportation of PE mulches, which costs approximately US$1,100 ha−1 in strawberry systems in Washington (DeVetter et al. Reference DeVetter, Zhang, Ghimire, Watkinson and Miles2017), whereas HMs do not need to be removed, thereby avoiding this substantial production cost, as well as preventing associated plastic pollution, which is associated with potentially substantial externalized environmental costs. To further validate this approach, hydromulching should be tested on a commercial scale in organic strawberry production.

Acknowledgments

We thank Keith Biggers, Kyle Radke, Peter Gregoire, and Warren Schmidt for providing technical support. We also thank Waqas Ahmad (Ph.D. graduate student), and various members of the Prischmann-Voldseth laboratory for helping to conduct this experiment.

Funding

This research was funded by grant 21-360 from the North Dakota Specialty Crop Block Grant Program.

Competing Interests

The authors declare they have no competing interests.